TECBOR® PYL - F LAMINATED PLASTERBOARD

Tecbor® PYL F Boards are rigid fire protection panels composed of laminated plaster specially formulated to resist fire, reinforced with glass fibres and fire retardants.

Tecbor® PYL F Boards contains high-quality natural plaster for indoor use and dry construction. Suitable for continuous ceilings, partition walls, selfsupporting and direct cladding, as well as for decorative purposes. Maximum flexibility allowing for irregular, curved or rounded shapes

Tecbor® PYL F is classified as A2-s1, d0 under European Standard EN 520.

At mcr tecresa® we constantly evolve and adapt to changing standards by developing new tests, conducted in official laboratories accredited by ENAC or similar international bodies under UNE EN, ASTM and other standards.

Our priority is the comprehensive development of Tecbor® PYL F, leads us to carry out tests for this type of plate: EN 520:2004+A1:2009 A.

Your Benefits

Product Documents

In accordance with Regulation (EU) 2016/679 of the European Parliament and of the Council of 27 April 2016, MCR TECRESA, S.L. informs you that the personal data you provide us with through this form will be processed by our company as the data controller for this website. The purpose of collecting and processing the personal data we request from you is to register you as a user of our services, which involves sending you our publications and offers, product and/or service promotions. Legitimacy is based on your own consent as the data subject. We inform you that the data you provide will not be transferred to third parties. You may exercise your rights of access, rectification, erasure, restriction of processing, portability and to be forgotten at rgpd@mcrtecresa.com, as well as the right to lodge a complaint with a supervisory authority. We suggest that you read the additional and detailed information in our Privacy Policy.

TECBOR PYL - F CONSTRUCTIVE SOLUTIONS

Suspended Ceilings

Fire-rated suspended ceilings are mainly used in two specific situations:

- The first is to vertically separate different fire compartments; this serves to confine the fire to where it started and prevent it from spreading between storeys. This solution is very useful in high-rise buildings, as inadequate compartmentation would cause the fire to advance more rapidly and lead to problems when evacuating.

- The second most common use is to protect elements above the ceiling, such as fixtures, structures, slabs, etc.

One of these options will be used depending on the needs of the situation. Our solutions have been tested against fire striking from below.

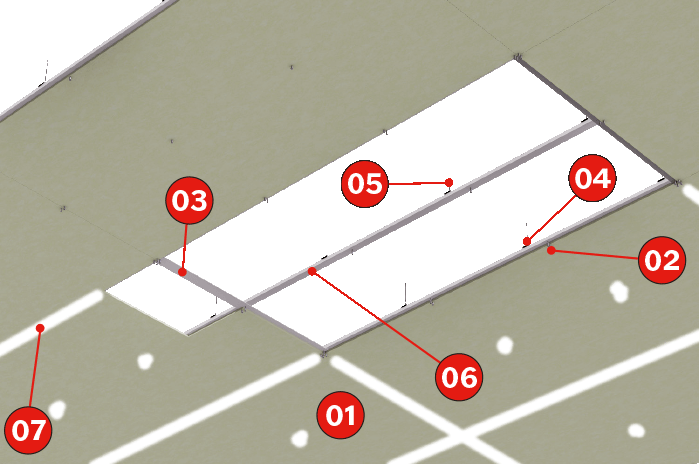

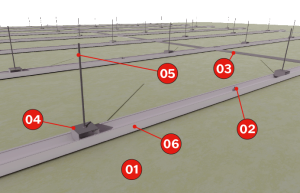

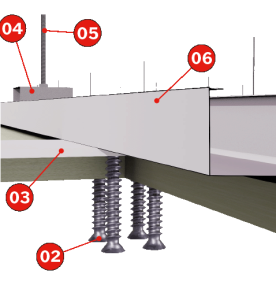

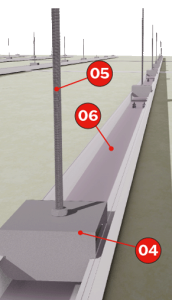

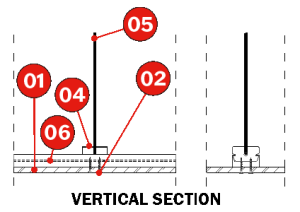

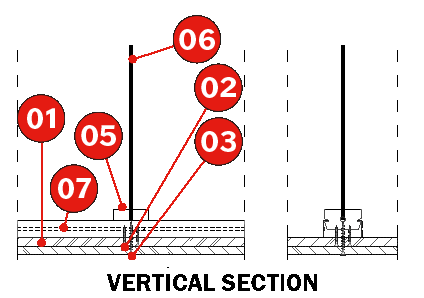

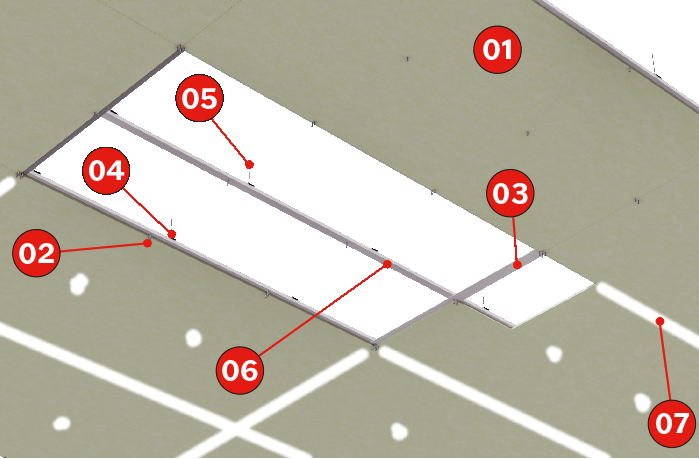

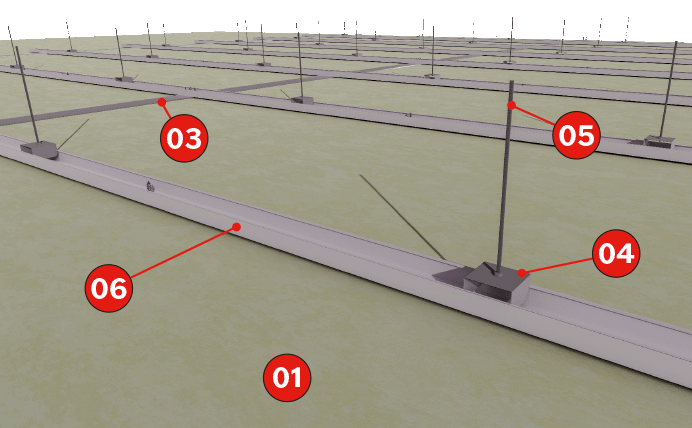

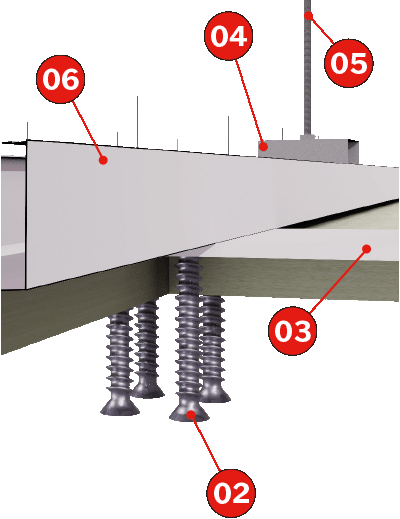

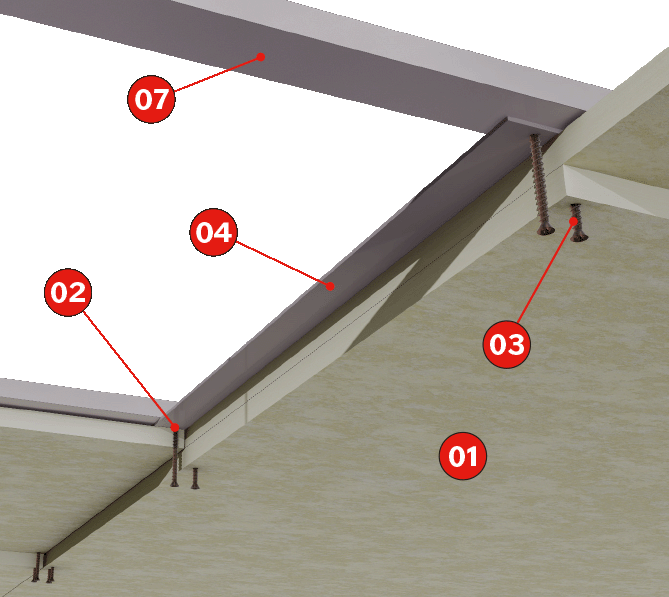

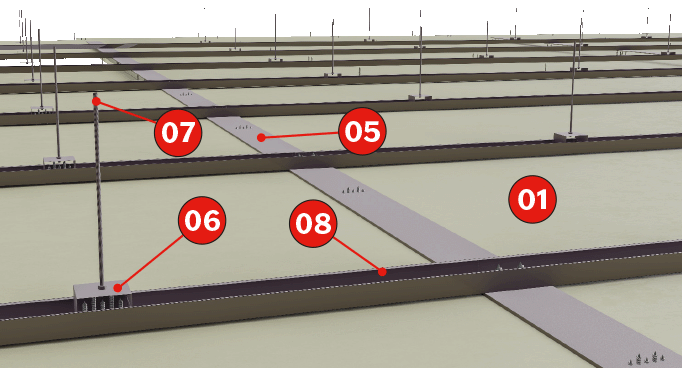

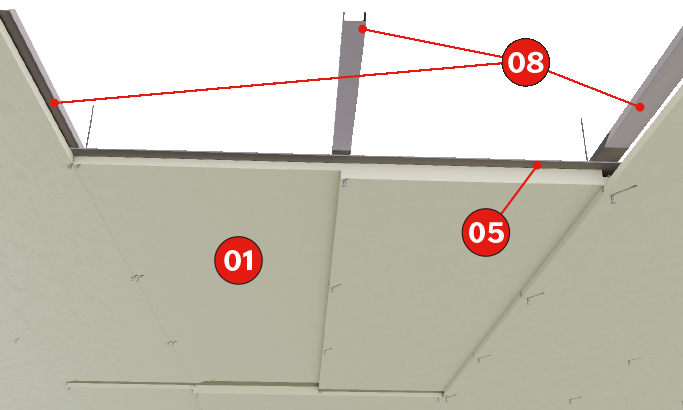

Description of Assenbly

The solution is created using 6 mm threaded metal rods to which the TC 60/27 are attached using the fork for TC 60/27. The TC 60/27 will be placed every 600 mm.

In the area where the lateral joint will be, coinciding with the short side of the Tecbor® PYL F Boards, the Tecbor® PYL Backing Steel Plate (70 mm wide and 0.6 mm thick sheet metal) is placed and screwed to the primary profiles.

Finally, the Tecbor® PYL F Boards are installed by being screwed to the primary profiles and to the sheet metal to form the lateral joint (3.5 x 25 mm self-drills screws every 250 mm), sealing all joints to the frame with Tecbor® Joint Paste.

Apply Tecbor® Joint Paste to the board joints and screw heads.

Solution

1. Tecbor® PYL-F 13 mm boards.

2. 3,5 x 25 mm self-drills screw.

3. Tecbor® PYL-F backing steel plate (70 mm wide and 0,6 mm thick sheet metal)

4. Clevis for TC 60/27.

5. M6 threaded rod.

6. TC 60/27.

7. Tecbor® Joing Paste.

Test

Standard: UNE EN 1364-2.

Laboratory: CERTIFuego.

Test Nº : 25_004_01.

Product Document

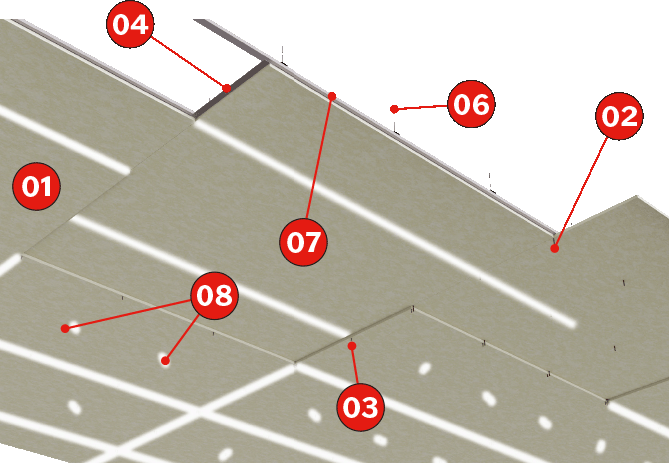

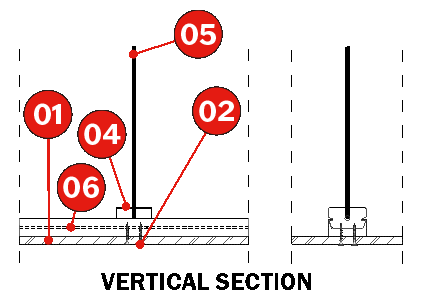

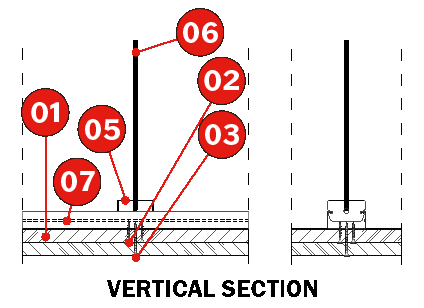

Description of Assenbly

The solution is created using 6 mm threaded metal rods to which the TC 60/27 are attached using the fork for TC 60/27. The TC 60/27 will be placed every 600 mm.

In the area where the lateral joint will be, coinciding with the short side of the Tecbor® PYL F Boards, the Tecbor® PYL Backing Steel Plate (70 mm wide and 0.6 mm thick sheet metal) is placed and screwed to the primary profiles.

Finally, the two layers 13 mm thick Tecbor® PYL F Boards are installed by being screwed to the primary profiles and to the sheet metal to form the lateral joint (3.5 x 25 mm self-drills screws every 250 mm (1st layer), and 3.5 x 55 mm every 250 mm (2nd layer), sealing all joints to the

frame with Tecbor® Joint Paste.

The longitudinal joints between gypsum boards are butted while the transverse joint is coincident in both layers.

Apply Tecbor® Joint Paste to the board joints and screw heads.

Solution

1. Tecbor® PYL-F 13 mm boards.

2. 3,5 x 25 mm self-drills screw.

3. 3,5 x 45 mm self-drills screw.

4. Tecbor® PYL backling steel plate (70 mm wide and 0,6 mm thick metal)

5. Clevis for TC 60/27.

6. M6 threaded rod.

7. TC 60/27.

8. Tecbor® Joing Paste.

Test

Standard: UNE EN 1364-2.

Laboratory: CERTIFuego.

Test nº: 25_004_02.

Product Document

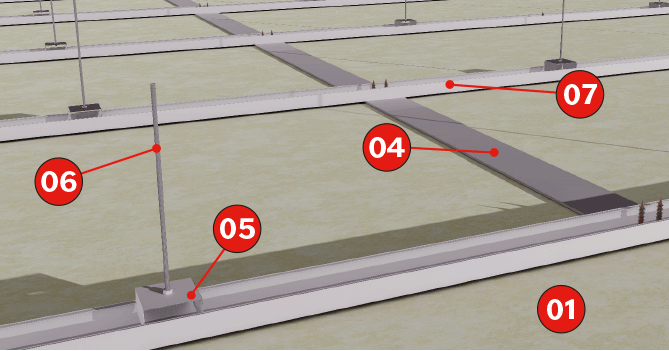

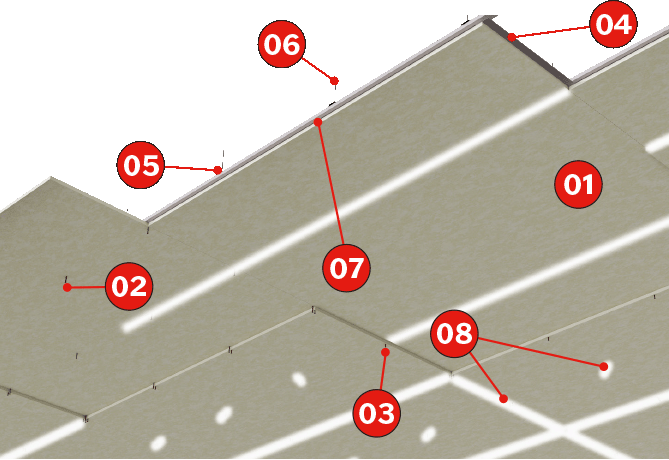

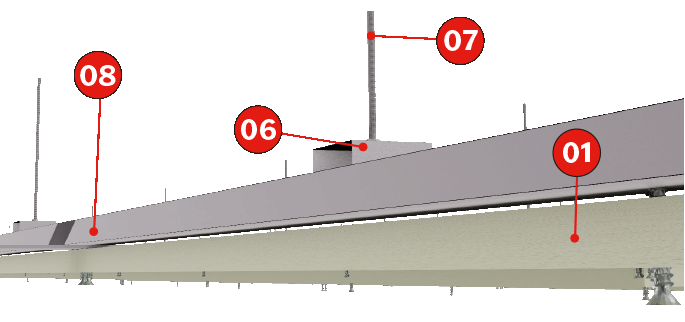

Description of Assenbly

The solution is created using 6 mm threaded metal rods to which the TC 60/27 are attached using the fork for TC 60/27. The TC 60/27 will be placed every 450 mm.

In the area where the lateral joint will be, coinciding with the short side of the Tecbor® PYL F Boards, the Tecbor® PYL Backing Steel Plate (70 mm wide and 0.6 mm thick sheet metal) is placed and screwed to the primary profiles.

Finally, the Tecbor® PYL F Boards are installed by being screwed to the primary profiles and to the sheet metal to form the lateral joint (3.5 x 35 mm self-drills screws every 250 mm), sealing all joints to the frame with Tecbor® Joint Paste.

Apply Tecbor® Joint Paste to the board joints and screw heads.

Solution

1. Tecbor® PYL-F 21 mm boards.

2. 3,5 x 25 mm self-drills screw.

3. Tecbor® PYL Backing Steel Plate (70 mm wide and 0,6 mm thick metal)

4. Clevis TC 60/27.

5. M6 threaded rod.

6. TC 60/27.

7. Tecbor® Joint Paste.

Test

Standard: UNE EN 1364-2.

Laboratory: CERTIFuego.

Test Nº: 25_003_01.

Product Document

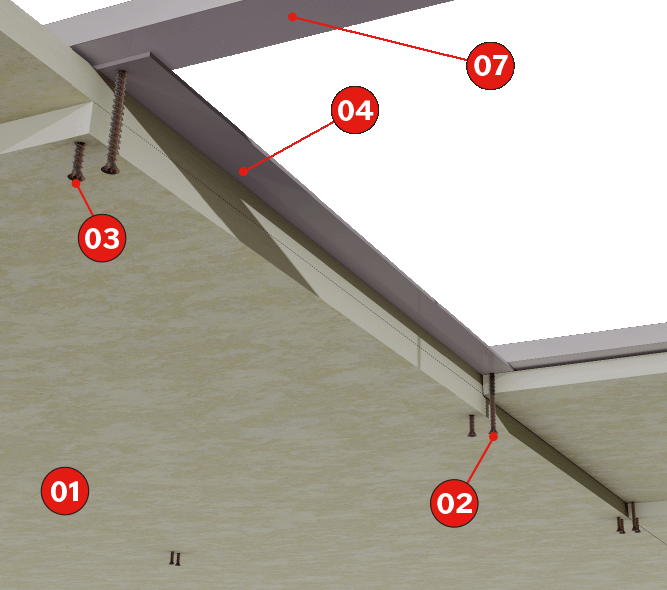

Description of Assenbly

The solution is created using 6 mm threaded metal rods to which the TC 60/27 are attached using the fork for TC 60/27. The TC 60/27 will be placed every 450 mm.

In the area where the lateral joint will be, coinciding with the short side of the Tecbor® PYL F Boards, the Tecbor® PYL Backing Steel Plate (70 mm wide and 0.6 mm thick sheet metal) is placed and screwed to the primary profiles.

Finally, the two layers 21 mm thick Tecbor® PYL F Boards are installed by being screwed to the primary profiles and to the sheet metal to form the lateral joint (3.5 x 35 mm self-drills screws every 250 mm in the first layer and 3.5 x 55 mm self-drills screws every 250 mm in the second layer), sealing all joints to the frame with Tecbor® Joint Paste.

The longitudinal joints between plasterboards are butted while the lateral joint overlaps both layers.

Apply Tecbor® Joint Paste to the board joints and screw heads.

Solution

1. Tecbor® PYL-F 21 mm Boards.

2. 3,5 x 25 mm self-drills screw.

3. 3,5 x 25 mm self-drills screw.

4. Tecbor® PYL Backing Steel Plate (70 mm wide and 0,6 mm thick sheet metal).

5. clevis for TC 60/27.

6. M6 threaded rod.

7. TC 60/27.

8. Tecbor® Joint Paste.

Test

Standard: UNE EN 1364-2.

Laboratory: CERTIFuego.

Test Nº: 25_003_02.

Product Document

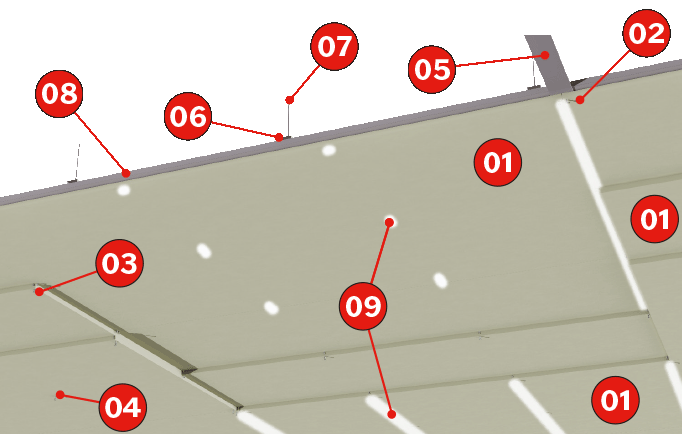

Description of Assenbly

The solution is created using 6 mm threaded metal rods to which the TC 60/27 are attached using the fork for TC 60/27. The TC 60/27 will be placed every 450 mm.

In the area where the lateral joint will be, coinciding with the short side of the Tecbor® PYL F Boards, the Tecbor® PYL Backing Steel Plate (70 mm wide and 0.6 mm thick sheet metal) is placed and screwed to the primary profiles.

Finally, the three layers 21 mm thick Tecbor® PYL F Boards are installed by being screwed to the primary profiles and to the sheet metal to form the lateral joint (3.5 x 35 mm self-drills screws every 250 mm in the first layer, 3.5 x 55 mm self-drills screws every 250 mm in the second layer and 3.5 x 80 mm self-drills screws every 250 mm in the third layer), sealing all joints to the frame with Tecbor® Joint Paste.

The longitudinal joints between plasterboards are butted while the lateral joint overlaps both layers.

Apply Tecbor® Joint Paste to the board joints and screw heads.

Solution

1. Tecbor® PYL-F 21 mm Boards.

2. 3,5 x 35 mm self-drills screw.

3. 3,5 x 55 mm self-drills screw.

4. 3,5 x 80 mm self-drills screw.

5. Tecbor PYL Backing Steel Plate (70 mm wide and 0,6 mm thick metal)

6. Clevis for TC 60/27.

7. M6 threaded rod.

8. TC 60/27.

9. Tecbor Join Paste.

Test

Standard: UNE EN 1364-2.

Laboratory: CERTIFuego.

Test Nº: 25_003_03.

Product Document

Fire-Rated Partitions Wall

Non-structural walls that separate fire compartments must be fire resistant as stipulated by UNE EN 1364-1.

When testing the fire resistance of non-structural elements (Part 1: Walls) and a free edge is left, the standard allows an increase in width.

Whenever the sectorisation of divisions is broken, such as with the passage of installations, it is necessary to seal the gaps produced by them.

Take a look at the Tecsel® Sealing Systems catalogue to find the best solution.

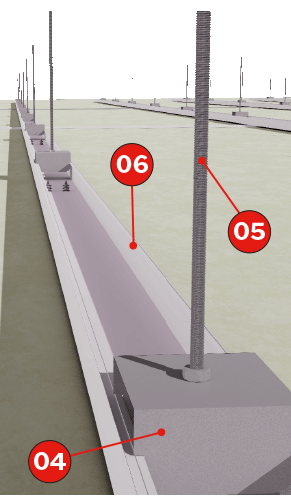

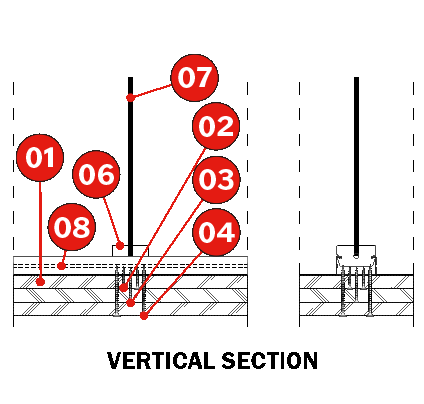

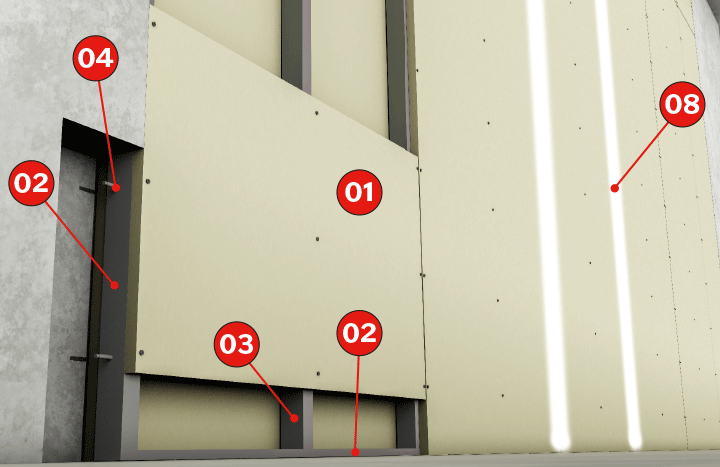

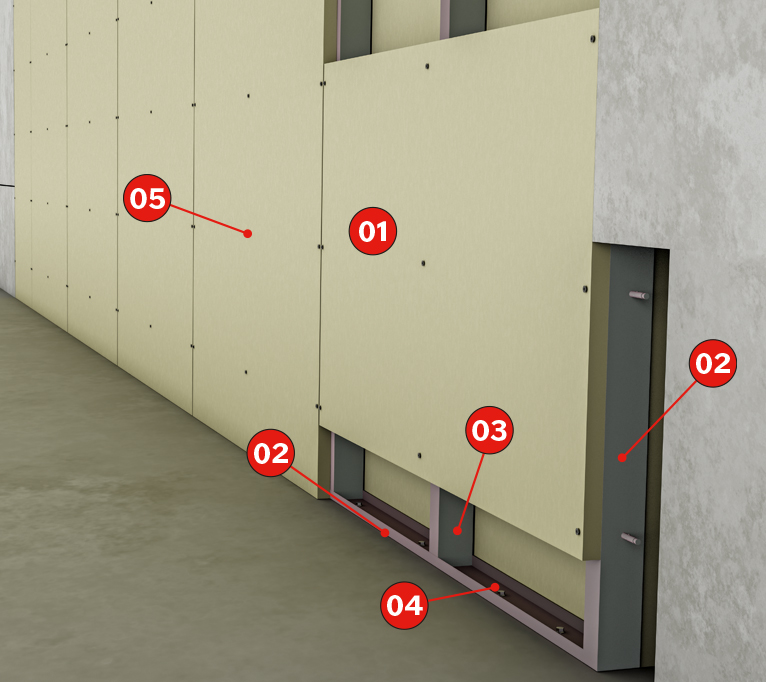

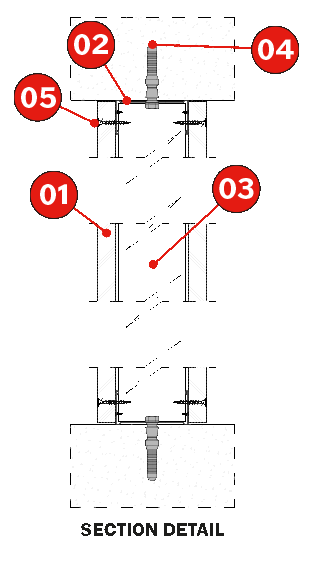

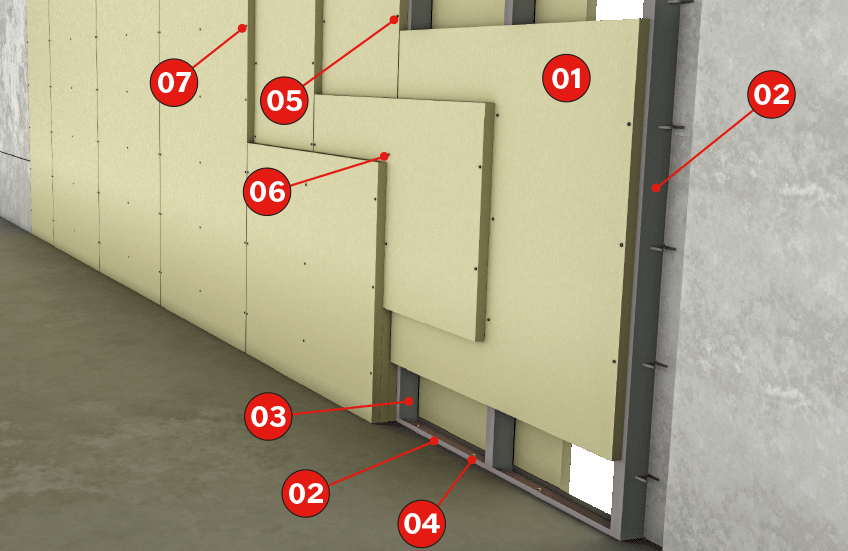

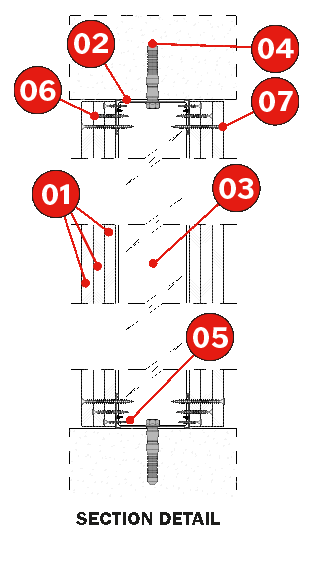

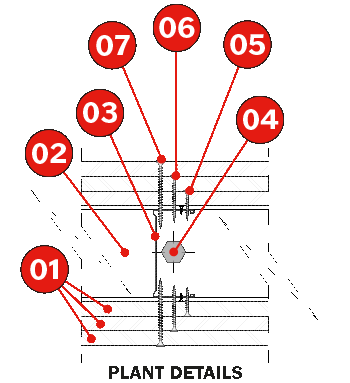

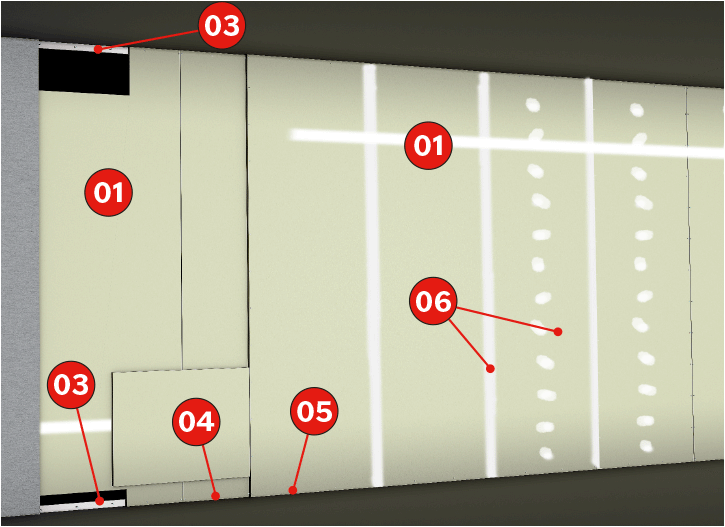

Description of Assenbly

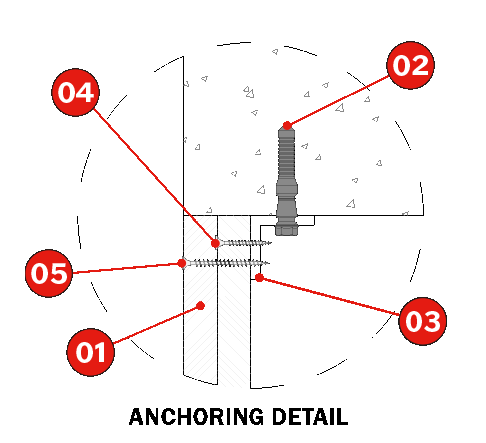

Fix the 48 mm perimeter channels to the floor, ceiling and adjoining walls with M-6 x 40 mm anchors every 550 mm. Assemble the 46 mm uprights every 450 mm.

We proceed to fix the layer of Tecbor® PYL F Boards 21 mm thick using 3.5 x 35 mm self-drills screws every 250 mm.

Apply Tecbor® Joint Paste to the board joints and screw heads.

Solution

1. Tecbor® PYL-F 21 mm Boards.

2. 48 mm perimeter runner.

3. 46 mm stud.

4. HILTI M6 x 40 mm anchor.

5. 3,5 x 35 mm self-drills screws.

6. Tecbor® Joint Paste.

Test

Standard: UNE EN 1364-1.

Laboratory: CERTIFuego.

Test Nº: 25_006_01.

Product Document

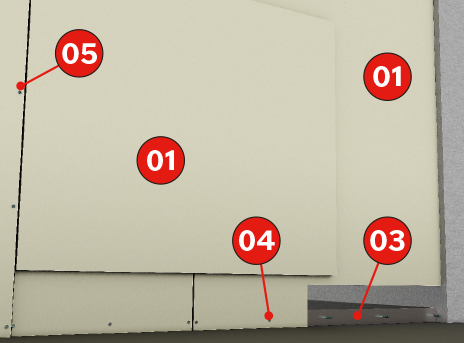

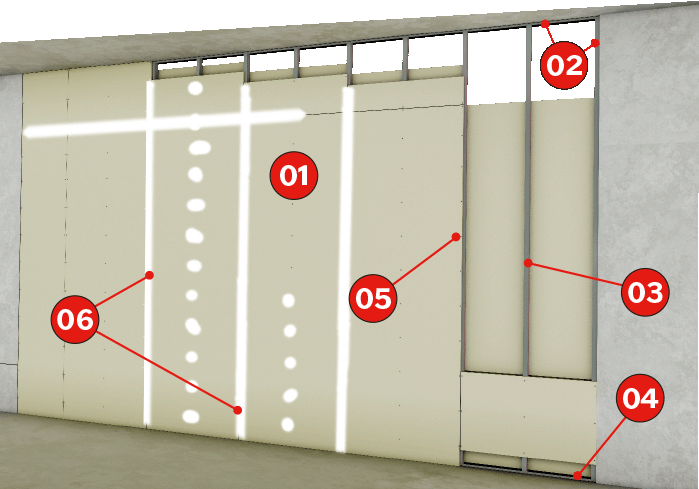

Description of Assenbly

Fix the 48 mm perimeter channels to the floor, ceiling and adjoining walls with M-6 x 40 mm anchors every 550 mm. Assemble the 46 mm uprights every 600 mm.

We proceed to fix the layer of Tecbor® PYL F Boards 13 mm thick using 3.5 x 35 mm self-drills screws every 250 mm (1st layer), 3.5 x 55 mm every 250 mm (2nd layer) and 3.5 x 80 mm every 250 mm (3rd layer).

Apply Tecbor® Joint Paste to the board joints and screw heads.

Solution

1. Tecbor® PYL-F 13 mm Boards.

2. 48 mm perimeter runner.

3. 46 mm stud.

4. HILTI M6 x 40 mm anchor.

5. 3,5 x 35 mm self-drills screws.

6. 3,5 x 55 mm self-drills screws.

7. 3,5 x 85 mm self-drills screws.

8 .Tecbor® Joint Paste.

Test

Standard: UNE EN 1364-1.

Laboratory: CERTIFuego.

Test Nº : 25_005_01.

Product Document

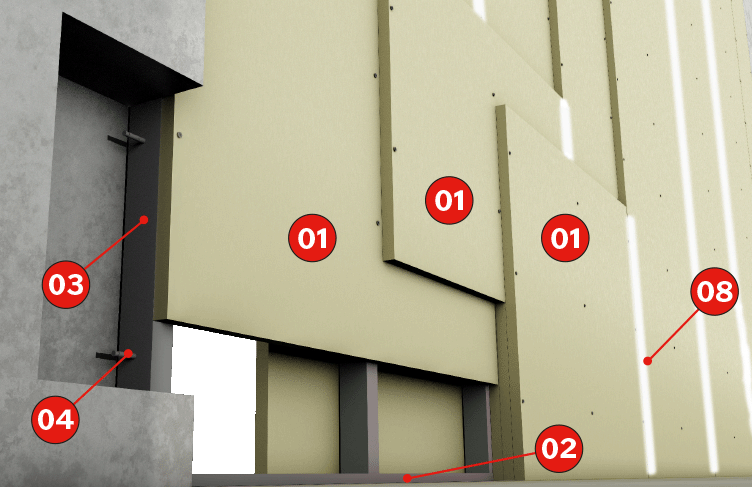

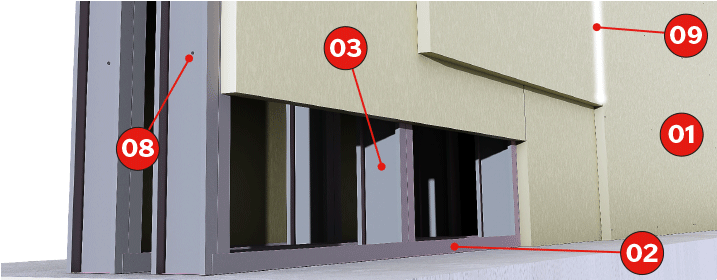

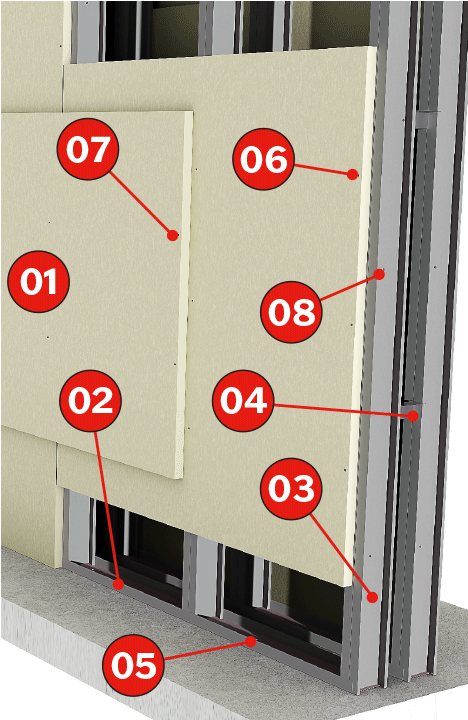

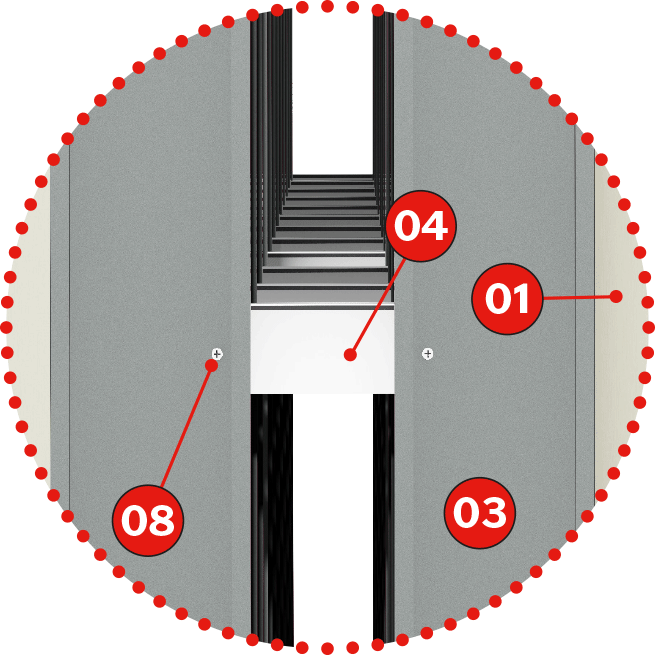

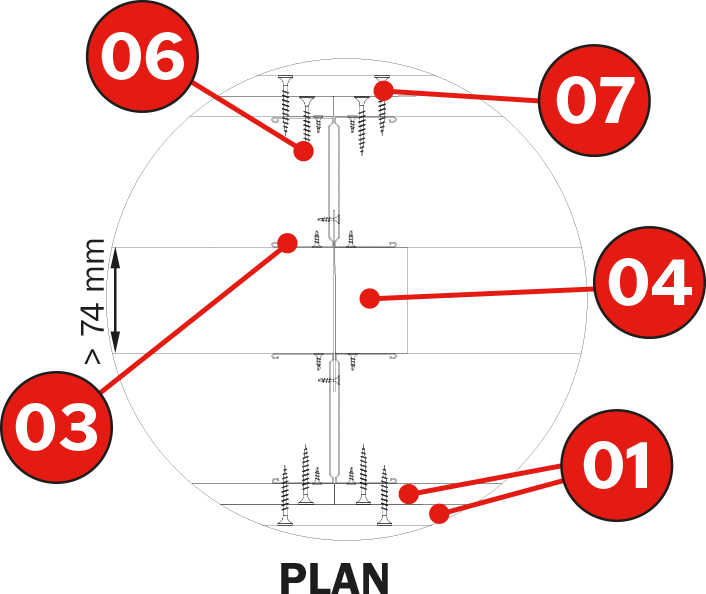

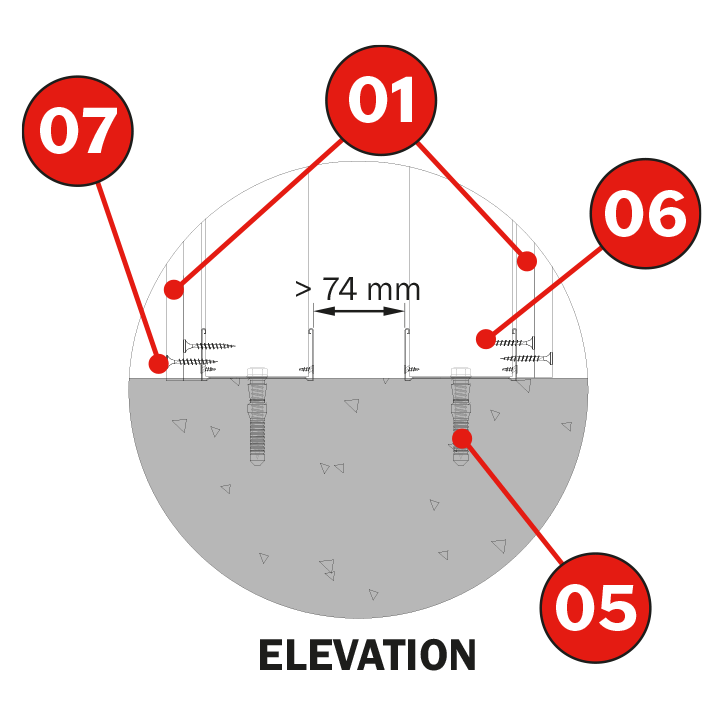

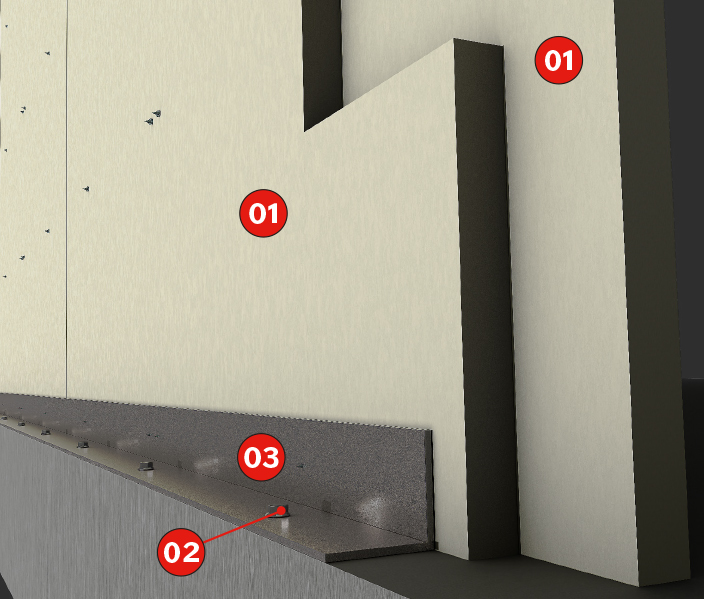

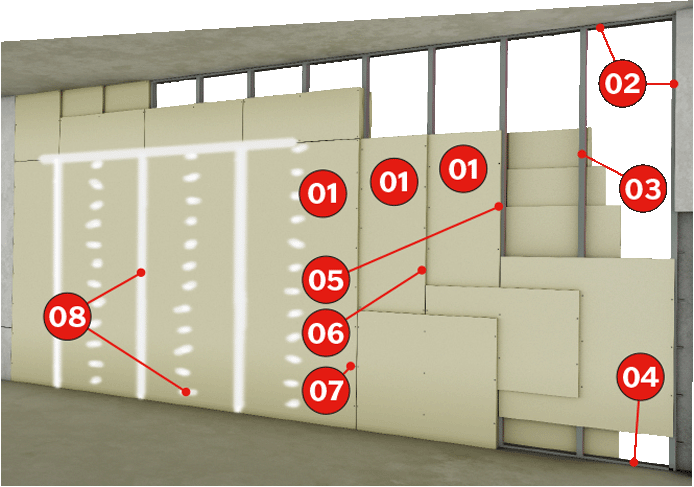

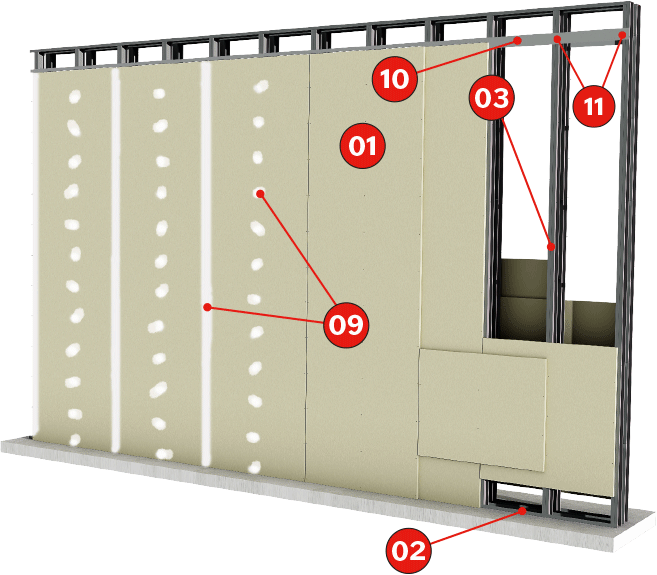

Description of Assenbly

Attach the 72 x 29 x 0.5 mm runners to the floor with M6 x 40 mm anchors every 550 mm, in two rows at least 74 mm apart. Assemble the 70 x 34 x 0.55 mm studs every 450 mm. The studs are screwed together in pairs with 25 mm sheet metal threaded screws to form an ‘H’.

The studs are attached to each other using 30 x 30 x 0.6 mm angle joints every 1000 mm going up (see 04).

70 x 0.6 mm flat sheet metal is also used as reinforcement horizontally, placed every 2500 mm (see 10).

Next we must attach the two vertically butted layers of Tecbor® PYL F Boards (2500 x 900 x 21 mm) together, using 3.5 x 35 mm self-drills screws every 250 mm (1st layer) and 3.5 x 55 mm every 250 mm (2nd layer).

Apply Tecbor® Joint Paste to the board joints and screw heads.

Solution

1. Tecbor® PYL-F 21 mm Boards.

2. 72 x 9 x 0,5 mm runner.

3. 70 x 34 x 0,55 mm stud.

4. 30 x30 x 0,6 mm metal angle joint.

5. HILTI M6 x 40 mm anchor.

6. 3,5 x 35 mm self-drills screws.

7. 3,5 x 55 mm self-drills screws.

8. 25 mm sheet metal threaded screws.

9. Tecbor® Joint Paste.

10. 70 x 0,6 mm reinforcing flat sheet metal.

11. 3,5 x 15 mm self-drills screws.

Test

Standard: UNE EN 1365-1.

Laboratory: APPLUS.

Test Nº: 23/30301479-1 M1.

Product Document

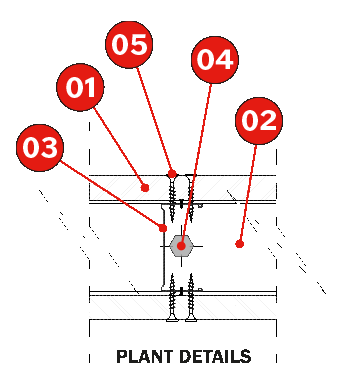

Wall Lining

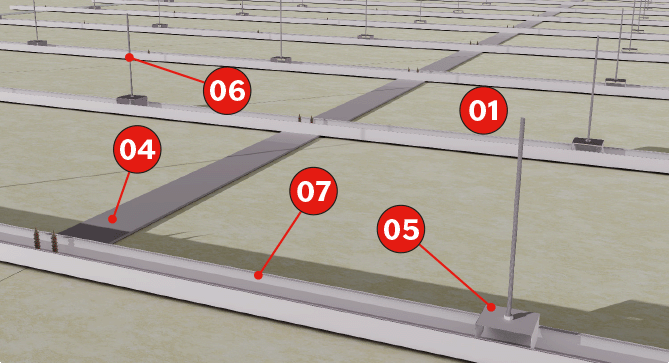

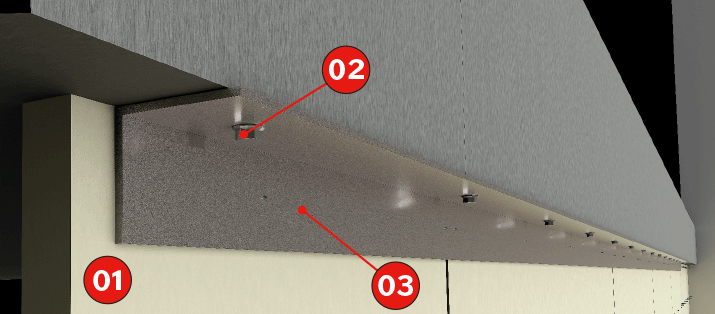

Description of Assenbly

Fixed angle brackets 30 x 30 x 0.6 mm to the floor and ceiling with M-6 x 40 mm anchors every 550 mm.

We now proceed to fix the 2 layers, vertically offset, of Tecbor® PYL F Boards 21 mm thick using 3.5 x 35 mm

self-drills screws every 250 mm (1st layer) and 3.5 x 55 mm every 250 mm (2nd layer).

Apply Tecbor® Joint Paste to the board joints and screw heads.

Solution

1. Tecbor® PYL-F 21 mm Boards.

2.HILTI M6 x 40 mm anchor.

3. 30 x 30 x 0,6 mm. angle.

4. 3,5 x 35 mm self-drills screws.

5. 3,5 x 55 mm self-drills screws.

6. Tecbor® Joint Paste.

Test

Standard: UNE EN 1364-1.

Laboratory: CERTIFuego.

Test Nº: 25_006_02.